The research group is equipped with up-to-date NVH measurement and analysis instrumentation including:

Instrumentation

Data acquisition systems: 4 multi-channel data acquisition systems up to 50 channels (Siemens LMS Scadas 310, 305, Mobile M2, NI Crio);

Sensors: more than 50 accelerometers (mono-axial, tri-axial, lightweight) (PCB and B&K), microphones (PCB), 1 impedence head (PCB), force sensor (Kistler), PU probe (Microflown), strain sensors (PCB), laser doppler vibrometer (Polytec), 6 tachometers probes, 1 hydrophone (B&K), 1 triangulation laser (MICRO-EPSILON).

Exciters: 3 modal impact hammer of different size (PCB), 2 electromagnetic shakers (The Modal Shop), Tri-axial electromagnetic skaker DongLing 3ES-10-HF)

Signal conditioning equipment: analogue and digital filters, digital signal processors.

Softwares: workstations and PC’s with licenses for all major CAE software for NVH analysis.

Test benches:

1. Rotor balancing machine (CEMB). Belt drive machine for small rotors. The special design of the driving system enables the machine to be operated both with the belt placed on top of the rotor and with the belt fixed in position under the rotor. The machine base plate can be simply rested on a working bench or bolted down to a solid base element.

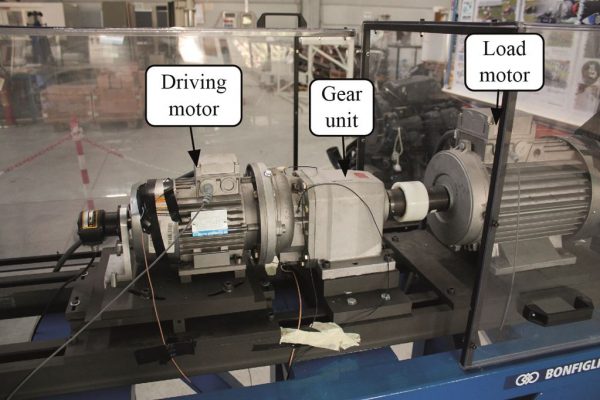

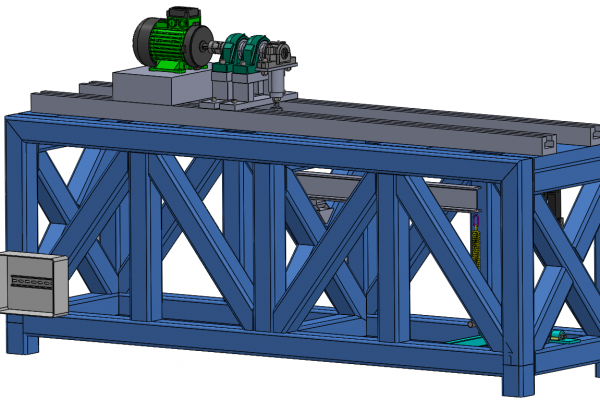

3. Test bench for gearboxes diagnosis. The test bench, developed in collaboration with Bonfiglioli Riduttori enables the experimental analysis of the vibro-acoustical behaviour of rotating machineries and the investigation of the vibration effects of different types of faults. The test bench consists of a base, including an induction driving motor controlled by inverter and a gear unit, while another motor applies the load torque; speed and torque are controlled by inverters.

2. Triaxial shaker 10kN (DongLing 3ES-10-HF and Siemens controller). –Sine Force: 10kN; Random Force: 10kN; Max payload: 100kg; Table size: 500X500 mm; frequency range: DC to 2kHz; Vel MAX: 1.2m/s; Acc MAX: 6g/8g. –Minimize the test time: three axes can reduce the testing time, shorter time than single axes.

–Reproduction reality environment: three axes shaker simulates reality dynamic environment more realistically than single shaker can do.

–Orthogonal Coupling Bearing Unit that uses high oil pressure and loading of hydrostatic bearing leading to not metal contact. Optimized throttle hole distribution to ensure the transmitting force.

–Siemens Controller: MIMO Random, MIMO Stepped Sine, MIMO swept Sine, MIMO Time Waveform Replicator for reproducing your own acceleration profile.

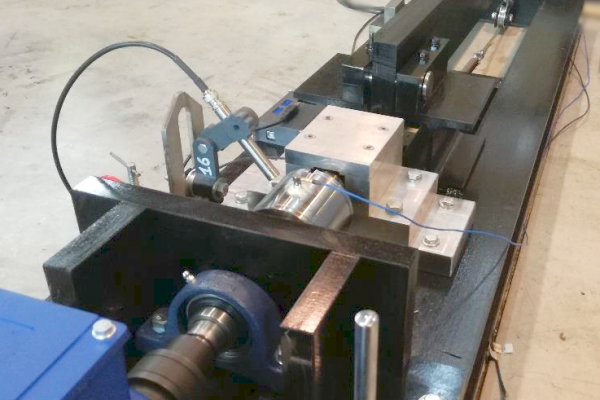

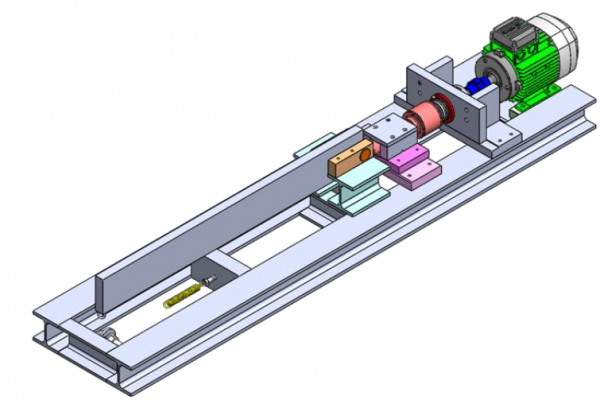

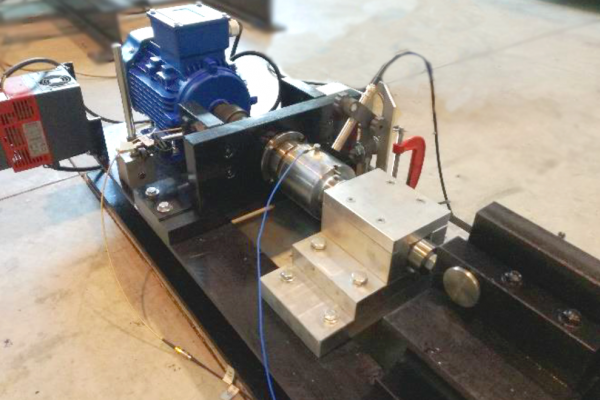

Bearing test benches

1. Dynamic durability (axial load)

The puprose is to verify the durability of the bearing under operating conditions. Dynamic test performed with bearing in rotation and subject to axial loading.

2. Tightness to infiltration

The purpose is to verify that the bearing remains fluid-tight and dust tight, disallowing the entry of water and dirty during the course of the test.

Dynamic test performed with the bearing in rotation, subject to a bending moment and exposed to an infiltration agent.

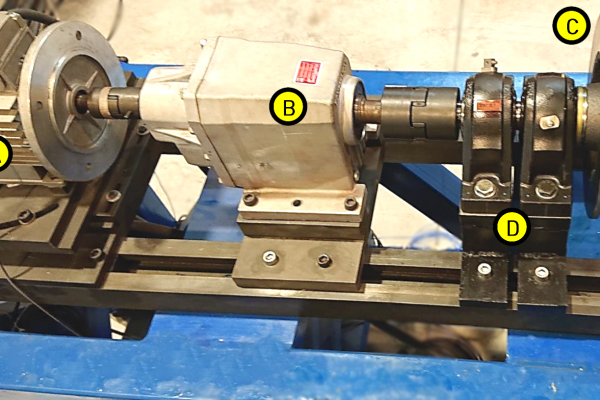

3. Drag torque

The purpose is to verify that the drag torque of the bearing, assembled with the interference specified in the drawing, is less than the prescribed value. The drag torque is the torque required for rotation of the outer ring with respect to the inner ring.

A.Electric Motor; B. Gearbox; C. Test Bearing; D. Support bearings; E. Load cell.

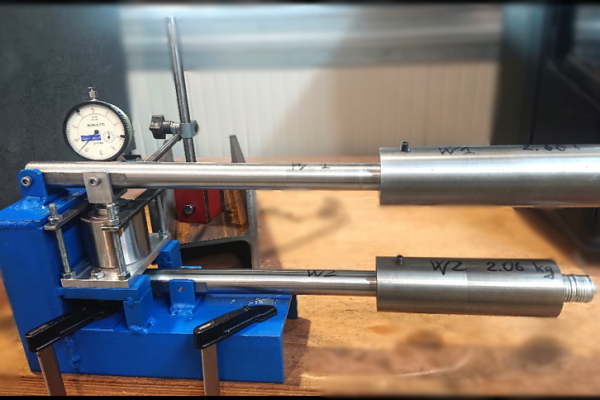

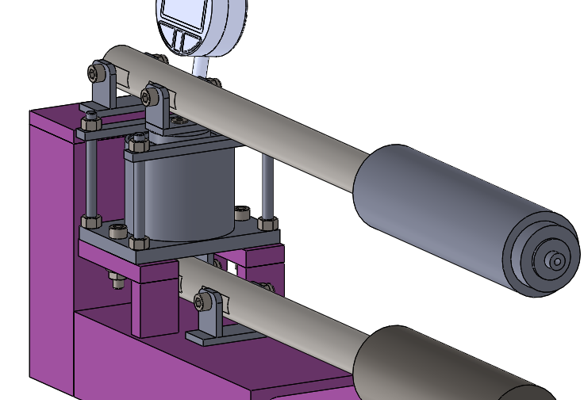

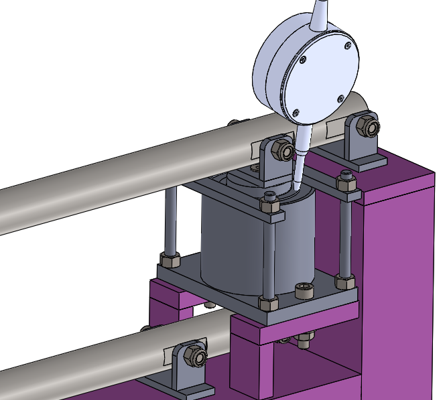

4. Axial clearance

The purpose is to check the axial clearance of the bearing rings. Test performed applying axial forces on the inner ring.

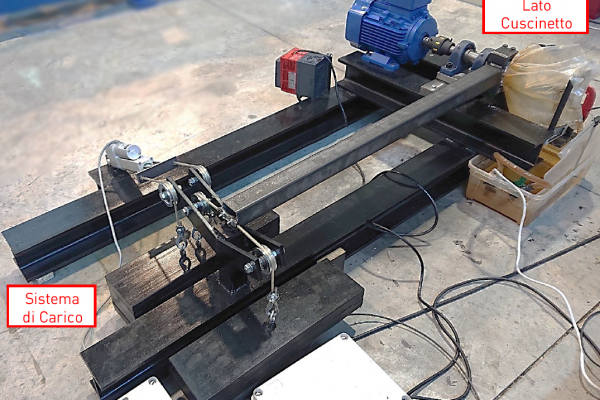

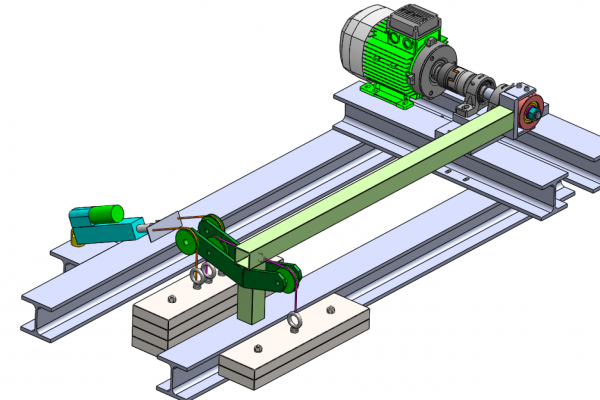

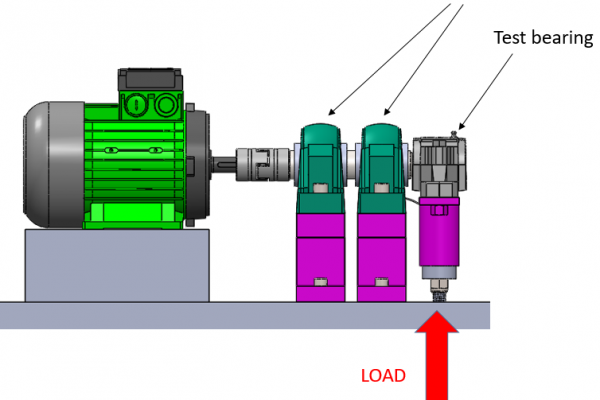

5. Dynamin durability (radial load)

The puprose is to verify the durability of the bearing under operating conditions. Dynamic test performed with bearing in rotation and subject to radial load.